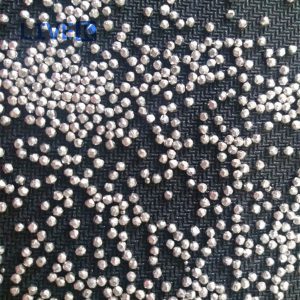

Steel Shot Abrasive also known as Ball Shot is a high performance is a spherical product of hypereutectoid steel in a heat treated tempered condition.

It has a uniform structure which provides optimum resilience and resistance to fatigue, and remains Round throughout its working life.

It used Impact rather than a cutting process, leaving minimal dust.

Detailed Specification

1. Steel shot size: S780, S660, S550, S460, S390, S330, S280, S230, S170, S110,S70

2. Chemical Composition of steel shot : C 0.70-1.20% Mn 0.60-1.20%, Si 0.40-1.20%, S≤0.05%, P ≤0.05%

3. Hardness: Normal: 40-50HRC Special: 52-56HRC, 56-60HRC Density: 7.4g/cucm

4. Steel shot is used for industrial foundry, forging plant, heat treatment shop, steel construction plant, container manufacturer, ship builder, auto and locomotive manufacturer .

5. Microstructure: Tempered Marten site High strength, durable Ervin life: Cast steel shot: 2000 cycles.

SAE stanadrd cast steel shot S330 S390 S460 S660 S930 for surface treatments and shot blasting

Description

Steel shot is spherical grains made of molten steel through an atomization (granulation) process, available in different sizes and hardnesses. It is used in airless wheel blast machines to clean foundry castings, surface polishing and shot peening.

Packed in 25kg bags

Special, stainless steel shot and high hardness specification shots available

Manufactured hypereutectoid steel abrasive

Grey, metal spheres

Used in airless wheel blast machines to clean foundry castings, surface polishing and shot peening

Also used in portable trackblast airless wheel blast machines for concrete floor preparation and profiling

Very long lasting

Can be recycled many times

Standardsfor steel shot:

SAE J827 Cast Steel Shot,

ISO11124-3High Carbon Cast Steel Shot and Grit.

YB/T5149-1993 Cast Steel Shot,

SFSA20-66Cast Steel Abrasive.

Specification for steel shot:

Project National Standards Quality

Chemical composition% C 0.85-1.20 0.85-1.0

Si 0.40-1.20 0.70-1.0

Mn 0.60-1.20 0.75-1.0

S <0.05 <0.030

P <0.05 <0.030

Hardness steel shot HRC40-50

HRC55-62 HRC44-48

HRC58-62

Density steel shot ≥7.20 g/cm3 7.4g/cm3

Microstructure Tempered Martensite or Troostite Tempered Martensite Bainite Composite organization

Appearance Spherical

Hollow particles<10%

Crack particle<15% Spherical

Hollow particles<5%

Crack particle<10%

Type S70 ,S110, S170, S230, S280, S330, S390, S460, S550, S660, S780

Packing Each ton in a separate Pallet and each ton divided in 25KG packs .

Durability 2500~2800 times

Density 7.4g/cm3

.Diameter 0.2mm,0.3mm,0.5mm,0.6mm,0.8mm,1.0mm,1.2mm,1.4mm,1.7mm,2.0mm,2.5mm

Applications 1.Blast cleaning: Used for blast cleaning of casting, die-casting, forging; sand removal of casting, steel plate, H type steel, steel structure. 2..Rust removal: Rust removal of casting, forging, steel plate, H type steel, steel structure.

3.Shot peening: Shot peening of gear, heat treated parts.

4.Shot blasting: Shot blasting of profile steel, ship board, steel board, steel material,steel structure. 5.Pre-treatment: Pre-treatment of surface, steel board, profile steel, steel structure, before painting or coating.

You must be logged in to post a review.

Reviews

There are no reviews yet.