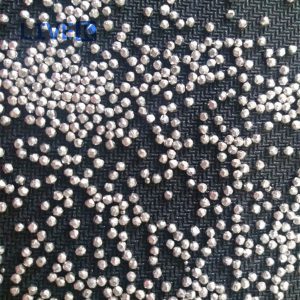

A Cut Wire Shot is developed by cutting wire into length equal to the wire’s diameter. Product quality is assured by controlling chemical & physical properties inherent in the wire and by accurate sizing. All the pieces are 100% solid. The cut wire is made available in an “As-Cut” i.e. cylindrical form and in conditioned/ spherical shape.

Size:

New wire/bright wire:45# 60# 80#

0.4mm,0.6mm,0.8mm,1.0mm,1.2mm,1.4mm,1.5mm,1.6mm,2.0mm

Hardness: 45# 45-50 HRC

60# 48-53 HRC

80# 52-57 HRC

Old wire/black wire (tyre wire /steel strand)

1.0mm, 1.2mm,1.5mm,2.0mm,2.5mm

Main technical indicators of steel cut wire shot:

Products Conditioned Carbon Steel Shot Carbon Steel Cut Wire Shot

Shape Conditioned (Spherical) As cut (Cylindrical)

Sizes

specifications From 0.2mm to 2.5mm

Standards AMS 2431, MIL-S-13165C, DIN8201, VDF 8001, SAEJ827, SAEJ441, JB/T8354

Chemical

composition Carbon (C) 0.45-0.75%

Manganese (Mn) 0.40-1.2%

Silicon (Si) 0.1-0.3%

Sulfur (S) ≤0.04%

Phosphorus (P) ≤0.04%

Microhardness 525~940 HV Vickers

51~68 HRC Rockwell

Tensile

intension 1350~2850 Mpa

Durability 3900 Times

(0.6mm, VDFI8001) 4000 Times

(0.6mm, VDFI8001)

Microstructure Deformed Sorbite

Density 7.8 g/cm3

Bulk density 4.5 g/cm3

Application

Blasting Cleaning of die casting, forgings sand removal, foundry pieces

Rust Removal of forgings, steel material, foundry pieces, steel board

Shot Blasting of steel board, profile steel, ship board, steel material

Shot Polishing of profile steel, steel board, and steel material

Shot Peening of heat treatment pieces, gears, etc.

Pre-treatment of surface steel structure (before painting)

Reviews

There are no reviews yet.